Proven Success: High-Mat Case Studies

Don't just take our word for it! Explore our case studies to see how High-Mat has transformed sheet metal visions into real-world success stories for clients across various industries. From optimizing the design and functionality of home comfort appliances to streamlining production processes for a portable evaporative cooler, our expertise delivers tangible results. We've even helped bring innovative plastic products to life with precision-crafted rotational molding dies. These are just a few examples of how High-Mat's comprehensive services can turn your sheet metal challenges into successful outcomes.

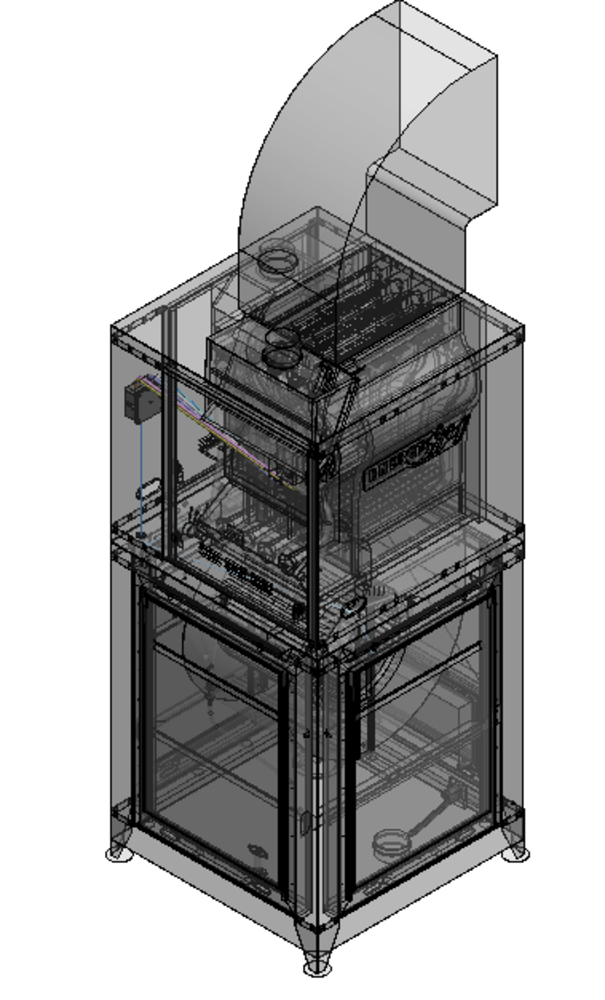

High-Mat Expertise Brings Efficiency to Home Comfort Appliances

High-Mat's engineering team played a key role in optimizing the design and functionality of sheet metal components for a gas heater, evaporative cooler, and water heater. Through close collaboration with the client, we ensured the designs prioritized manufacturability, resulting in significant cost savings and a faster time to market for the client's product line. Our detailed shop drawings facilitated clear communication with the fabrication partner, guaranteeing a smooth and efficient production process.

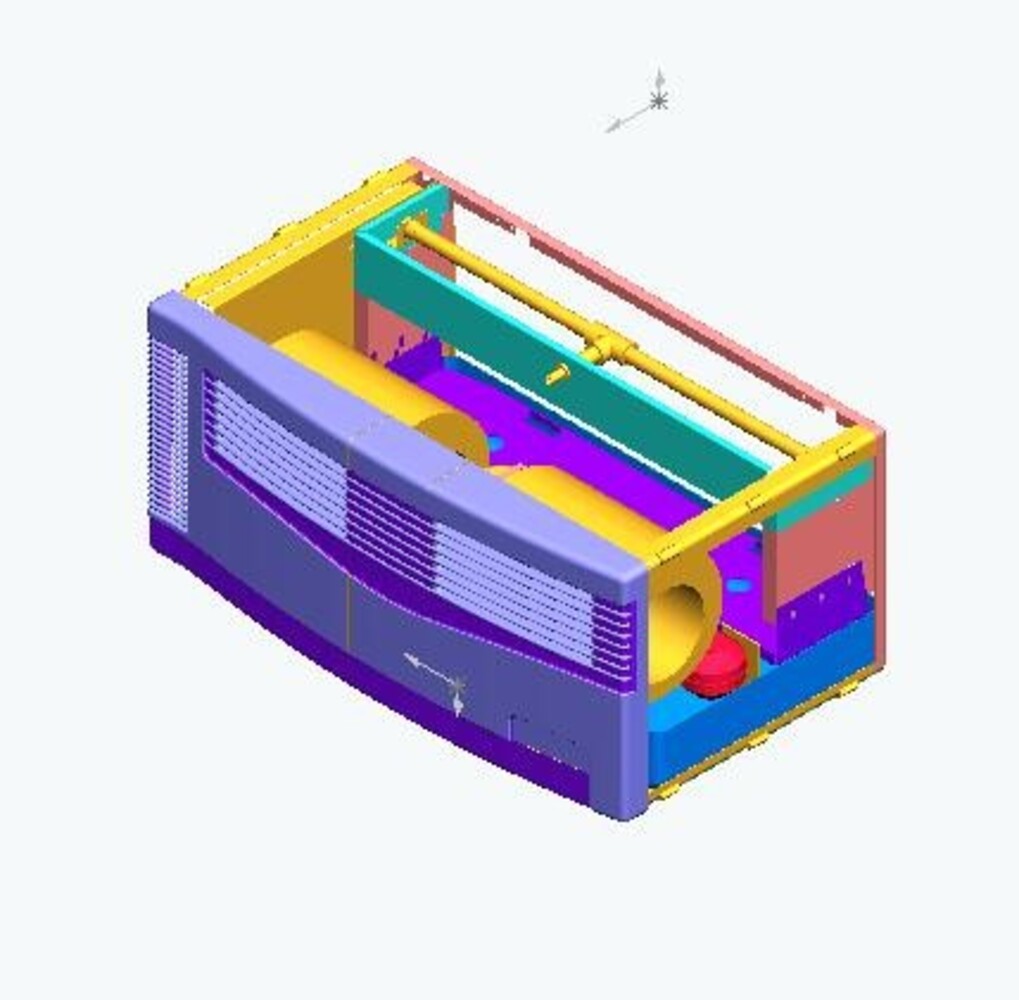

Streamlining Production for a Portable Evaporative Cooler

High-Mat's engineering team leveraged powerful software tools to design a portable evaporative cooler, incorporating both custom parts and optimized sheet metal components. We collaborated closely with the client throughout the process, prototyping and testing the design to ensure optimal functionality. Once finalized, our detailed manufacturing drawings facilitated a smooth transition to mass production.

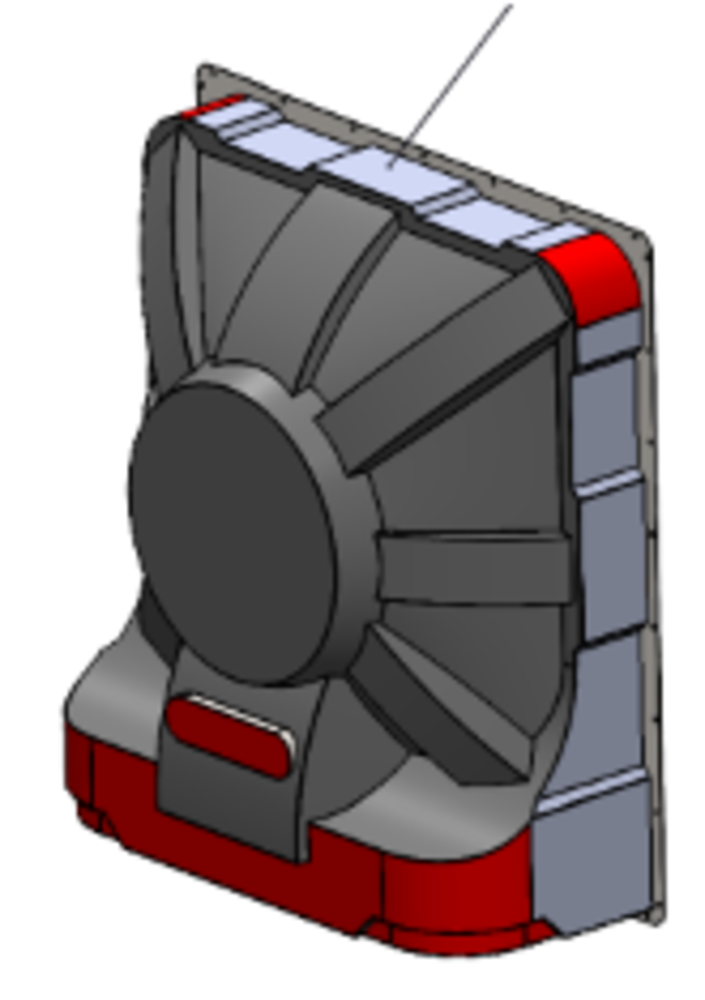

Bringing Plastic Products to Life with Precision Molds

High-Mat's expertise extends beyond sheet metal. In this project, we collaborated with the client to design a plastic product. After finalizing the design, our engineers meticulously crafted the rotational molding die, ensuring it met the highest standards for production. Detailed shop drawings were then generated to guide the die manufacturing process, guaranteeing an accurate and efficient build.